The Global Electron Beam Machining Market is witnessing consistent advancements as precision manufacturing and micro-machining technologies continue to evolve. Electron beam machining (EBM) is a high-precision thermal process that uses a focused beam of high-velocity electrons to erode materials with minimal thermal distortion. This makes it particularly valuable in aerospace, automotive, medical device manufacturing, and microelectronics where intricate cuts and high tolerances are essential.

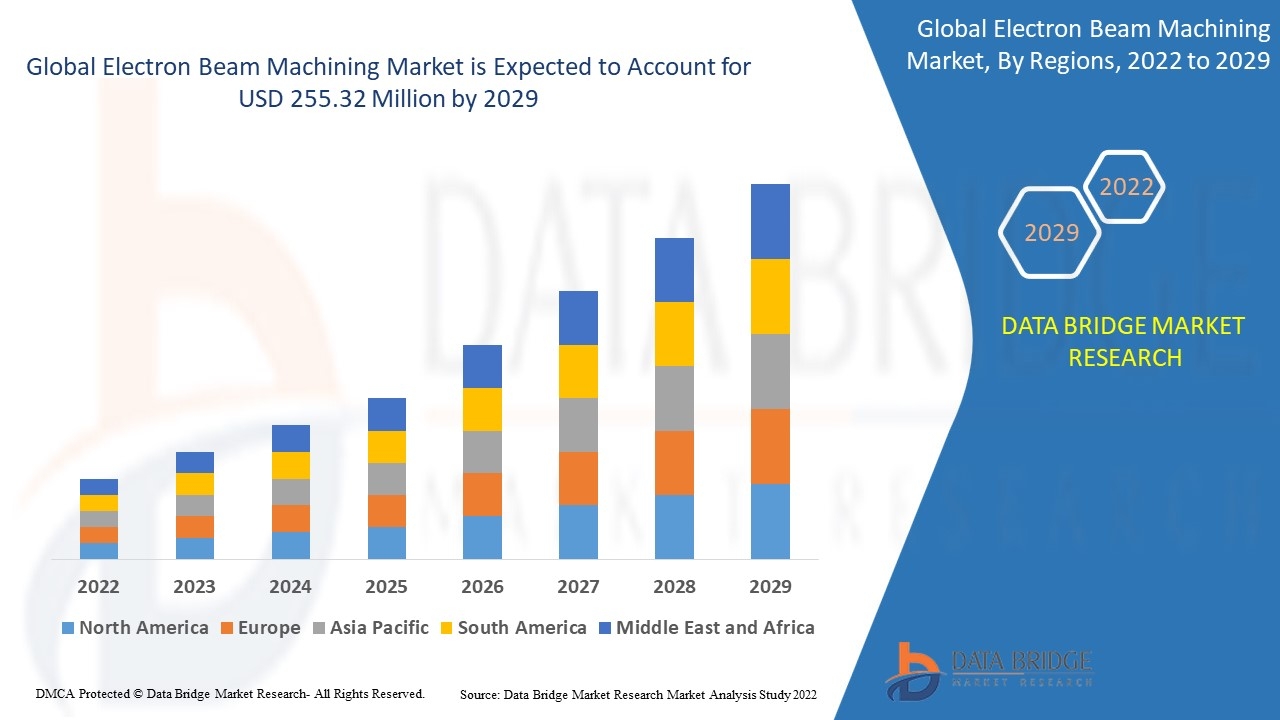

Data Bridge Market Research reports that the global electron beam machining market was valued at USD 193.89 million in 2021 and is expected to reach USD 255.32 million by 2029, registering a CAGR of 3.50% during the forecast period of 2022–2029. This steady growth reflects surging demand for advanced manufacturing technologies that can deliver high precision while maintaining cost efficiency.

Request a sample of the Global Electron Beam Machining Market report

👉 https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-electron-beam-machining-market

Market Definition

Electron beam machining (EBM) is a non-contact, thermal machining process that utilizes a focused beam of electrons to remove material from a workpiece. The high kinetic energy of the electrons, when converted into heat upon impact, vaporizes or melts the target surface. Because EBM produces little to no mechanical stress or heat-affected zone (HAZ), it is ideal for machining hard materials such as superalloys, refractory metals, and composites.

The process finds applications in industries requiring extreme precision—such as aerospace turbine blades, medical implants, and high-frequency electronics—making it a critical technology in the broader precision engineering landscape.

Market Dynamics: Drivers

Several factors are driving growth in the global electron beam machining market:

Precision Requirements in Advanced Industries

Industries such as aerospace, defense, and medical devices require manufacturing processes capable of ultra-fine cuts and minimal distortion, which EBM reliably delivers.

Rising Adoption of Lightweight and High-Strength Materials

Materials such as titanium alloys and nickel superalloys are increasingly used for performance applications. Conventional machining often struggles with these materials, whereas EBM provides precise control with reduced wear on tooling.

Technological Enhancements

Innovations in electron optics, vacuum systems, real-time monitoring, and automation are improving process stability, reducing cycle times, and expanding the technology’s applicability.

Shift Toward Smart Manufacturing

Integration of EBM systems with Industry 4.0 platforms enables enhanced process monitoring, predictive maintenance, and data-driven optimization, which appeals to modern manufacturers.

Market Segmentation

The global electron beam machining market is segmented to provide comprehensive insight into key growth areas:

By Type

Wire Electron Beam Machining

Coil Electron Beam Machining

**Others

By End-User Industry

Aerospace

Automotive

Healthcare & Medical Devices

Electronics & Semiconductor

Energy

**Others

By Application

Micro-Machining

Precision Cutting

Drilling

Grooving

**Others

These segments help stakeholders identify high-growth opportunities across technology types and industrial uses.

Inquire here to explore industry-specific data

👉 https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-electron-beam-machining-market

Competitive Landscape

The electron beam machining market is moderately competitive, with both established technology providers and specialized precision machining companies participating. Key players focus on:

Product Innovation: Developing EBM systems with improved electron gun stability, enhanced beam control, and automated vacuum environments.

Strategic Partnerships: Collaborations with OEMs and research institutions to tailor machining solutions for industry-specific challenges.

After-Sales Support: Strengthening global service networks to ensure uptime and maximize customer productivity.

Major industry participants also invest in digital interfaces, predictive diagnostics, and user-friendly control software to broaden adoption across diverse manufacturing sectors.

Emerging Opportunities

The electron beam machining market presents several forward-looking opportunities:

Rising Adoption in Microelectronics

As consumer demand for smaller, more powerful electronic components grows, EBM’s ability to machine micro-features with precision positions it as a key technology for advanced electronics manufacturing.

Growth in Additive Manufacturing Integration

Hybrid manufacturing systems that combine additive processes (such as electron beam melting) with precision machining offer new efficiency and performance benefits for complex parts.

Expansion in Medical Devices

EBM’s capability to machine biocompatible materials with minimal microstructure alteration is driving its use in surgical tools, implants, and orthopedic applications.

Customization and Digital Process Control

Manufacturers are leveraging advanced process control and digital twins to reduce defects, enhance repeatability, and scale precision operations.

Regional Analysis

North America

North America holds a prominent market share due to strong aerospace and defense sectors, robust R&D infrastructure, and early adoption of advanced manufacturing technologies.

Europe

Countries such as Germany, France, and the UK drive Europe’s electron beam machining market due to high precision engineering demand in automotive, aerospace, and industrial automation.

Asia-Pacific

Asia-Pacific is projected to grow rapidly, spurred by manufacturing expansion in China, India, South Korea, and Japan. Investments in advanced manufacturing technologies and increased industrial automation support regional growth.

Latin America and Middle East & Africa

These regions are gradually adopting precision fabrication technologies, supported by investments in industrial infrastructure and participation in global supply chains.

Frequently Asked Questions (FAQs)

Q1. What is electron beam machining (EBM)?

Electron beam machining is a thermal, non-contact process that removes material using a focused beam of high-velocity electrons to achieve precise, low-distortion cuts.

Q2. Which factors are driving the EBM market?

Growing precision requirements in aerospace and medical sectors, adoption of advanced materials, and Industry 4.0 integration are key drivers.

Q3. Which industry leads the electron beam machining demand?

Aerospace remains a primary end-user, due to stringent precision and performance specifications.

Q4. What is the projected CAGR from 2022–2029?

The electron beam machining market is expected to register a CAGR of 3.50% during the forecast period.

Access the Full Report

Access the full “Global Electron Beam Machining Market” Report here

👉 https://www.databridgemarketresearch.com/checkout/buy/global-electron-beam-machining-market/compare-licence

For More Reports

About Us

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact:

Data Bridge Market Research Private Ltd.

3665 Kingsway — Suite 300

Vancouver BC V5R 5W2, Canada

📞 +1 614 591 3140 (US)

📞 +44 845 154 9652 (UK)

✉ Email: Sales@databridgemarketresearch.com

🌐 Website: https://www.databridgemarketresearch.com/