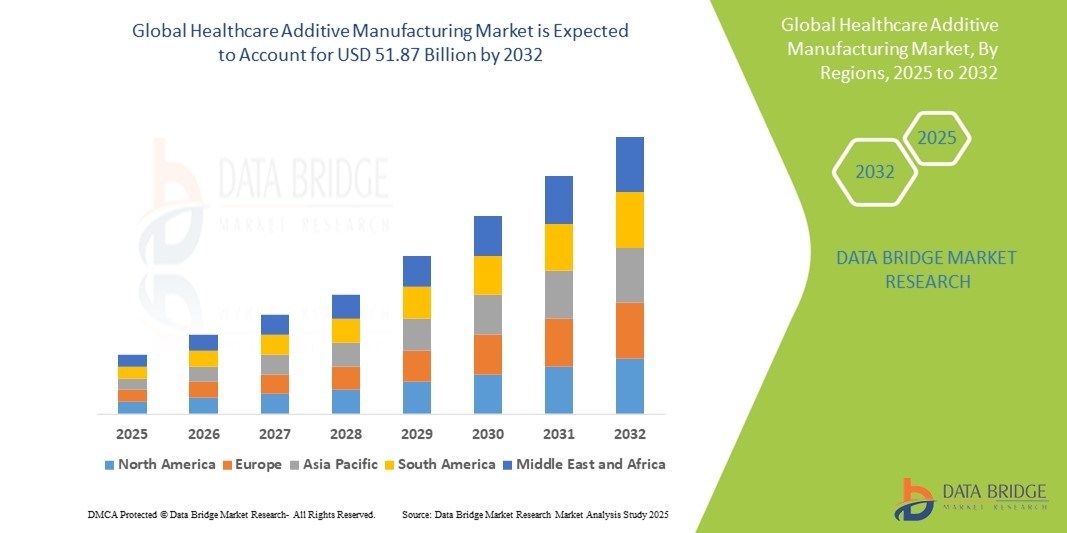

The Global Healthcare Additive Manufacturing Market is on a transformative growth trajectory as healthcare systems worldwide adopt advanced manufacturing technologies to enhance patient outcomes, reduce production costs, and accelerate personalized care solutions. The global healthcare additive manufacturing market size was valued at USD 10.92 billion in 2024 and is expected to reach USD 51.87 billion by 2032, growing at a robust CAGR of 21.50% during the forecast period. This substantial growth underscores the rising integration of 3D printing technologies across medical devices, implants, prosthetics, bioprinting, and surgical tools, which are reshaping clinical practices and supply chain dynamics.

Healthcare additive manufacturing enables rapid prototyping, customization, and on-demand production of complex geometries that are difficult to fabricate using conventional methods. As technological advancements continue to reduce manufacturing barriers, the adoption of additive processes is accelerating across hospitals, medical research institutions, and manufacturing networks.

Request a sample of “Global Healthcare Additive Manufacturing Market” report

@ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-healthcare-additive-manufacturing-market

Market Definition and Scope

Healthcare additive manufacturing refers to the use of layer-by-layer fabrication techniques—commonly known as 3D printing—to produce medical components, products, and scaffolds that are tailored to individual patient anatomy and clinical needs. Applications include orthopedics, dental prosthetics, surgical instruments, bioprinted tissues, implants, and customized medical tools.

Unlike traditional subtractive manufacturing, additive manufacturing (AM) enables precise control over geometry, material distribution, and structural properties, leading to reduced waste, faster production cycles, and enhanced design flexibility. This is particularly valuable in personalized medicine, where patient-specific solutions are increasingly in demand.

Key Market Drivers

Several strategic factors are driving robust growth in the global healthcare additive manufacturing market:

Demand for Personalized Healthcare Solutions: The shift toward patient-specific implants, prosthetics, and surgical models is a primary driver. Additive manufacturing enables customization that traditional manufacturing cannot economically match.

Technological Advancements: Ongoing innovations in materials science (biocompatible polymers, metals, ceramics) and printing technologies (SLA, SLS, DMLS, bioprinting) are expanding application scopes and improving clinical outcomes.

Cost and Time Efficiency: Additive processes reduce lead times and inventory costs while enabling on-site production of complex parts, which is especially advantageous in remote healthcare facilities or emergency scenarios.

Growth in Chronic Diseases and Surgical Procedures: Rising incidence of orthopedic conditions, dental disorders, and surgical interventions is increasing the demand for bespoke implants, supportive devices, and surgical planning models.

Market Segmentation: Identifying Strategic Opportunities

To support targeted investment and product strategy, the healthcare additive manufacturing market can be segmented as follows:

By Technology: Includes stereolithography (SLA), selective laser sintering (SLS), direct metal laser sintering (DMLS), fused deposition modeling (FDM), and bioprinting. Bioprinting is gaining rapid attention for its application in tissue engineering and regenerative medicine.

By Material: Key materials include polymers, metals, ceramics, and composites. Biocompatible polymers and medical-grade metals (such as titanium and stainless steel) are widely used in implants and prosthetics.

By Application: Segments include surgical tools, implants, prosthetics & orthotics, anatomical models, tissue engineering, dental applications, and drug delivery systems. Implants and prosthetics dominate due to high customization demand.

By End User: Hospitals, dental clinics, research institutions, medical device manufacturers, and contract manufacturing organizations (CMOs) are primary users. Hospitals and CMOs are increasingly adopting additive systems to support in-house production and rapid prototyping.

By Geography: The market is analyzed across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Adoption rates are influenced by healthcare infrastructure, regulatory frameworks, and innovation ecosystems.

Competitive Landscape: Winning Strategies

The competitive landscape in the global healthcare additive manufacturing market is characterized by rapid innovation, strategic partnerships, and expanding manufacturing capabilities. Key players are focusing on differentiation through technology advancements, ecosystem collaborations, and enhanced service offerings.

Inquire here to explore industry-specific data

@ https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-healthcare-additive-manufacturing-market

Key strategies adopted by leading companies include:

Product Innovation: Development of advanced additive systems and biocompatible materials that meet stringent clinical requirements.

Collaborations with Healthcare Providers: Partnerships with hospitals, surgical centers, and research institutions facilitate real-world validation and accelerate clinical adoption.

Geographical Expansion: Establishing regional service centers and production hubs to serve localized markets and reduce supply chain disruptions.

Regulatory Compliance Focus: Ensuring product and process compliance with FDA, EMA, and other regional healthcare authorities enhances trust and speeds time-to-market.

Emerging Trends and Market Opportunities

Several emerging trends are shaping the future of healthcare additive manufacturing:

Bioprinting and Tissue Engineering: Bioprinting technologies that enable the fabrication of tissue scaffolds and regenerative constructs are expected to unlock new therapeutic possibilities.

Hybrid Manufacturing Models: Combining additive and traditional manufacturing approaches for optimized production efficiency and cost-effectiveness.

AI-Driven Design and Automation: Use of artificial intelligence (AI) and machine learning to optimize print designs, material usage, and post-processing workflows.

On-Demand Manufacturing: Growing demand for localized, on-site production of surgical tools and patient-specific devices, particularly in remote or resource-limited settings.

Regional Analysis: Growth Hotspots

North America: Dominates the market due to advanced healthcare infrastructure, high R&D investments, strong adoption of digital technologies, and favorable reimbursement frameworks.

Europe: Exhibits steady growth driven by rising healthcare expenditures, regulatory stability, and strong presence of major additive manufacturing players.

Asia-Pacific: Expected to register the fastest growth, supported by expanding healthcare infrastructure, increasing government support for medical innovation, and rising incidence of chronic diseases requiring surgical interventions.

Latin America & Middle East/Africa: Growth is supported by improving healthcare access, digital modernization initiatives, and partnerships that enable technology transfer and capability building.

Frequently Asked Questions (FAQs)

What is healthcare additive manufacturing?

Healthcare additive manufacturing uses 3D printing technologies to produce medical parts—such as implants, prosthetics, surgical tools, and tissue models—layer by layer with high customization and precision.

What is driving the market’s rapid growth?

Key drivers include personalized medicine demand, technological innovation, cost/time efficiencies, and rising surgical procedures.

Which application segment holds the largest share?

Implants and prosthetics command a significant market share due to high customization requirements.

Which region is the fastest-growing?

Asia-Pacific is anticipated to grow the fastest due to expanding healthcare infrastructure and innovation adoption.

Access the Full Market Report

Access the full “Global Healthcare Additive Manufacturing Market” Report here

@ https://www.databridgemarketresearch.com/checkout/buy/global-healthcare-additive-manufacturing-market/compare-licence

For More Reports

Explore a comprehensive range of market intelligence covering healthcare technology, industrial 3D printing, consumer goods, advanced materials, and emerging innovation sectors.

About Us

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact:

Data Bridge Market Research Private Ltd.

3665 Kingsway — Suite 300

Vancouver BC V5R 5W2 Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)

Email: Sales@databridgemarketresearch.com

Website: https://www.databridgemarketresearch.com/