The Healthcare Additive Manufacturing Market has emerged as one of the most transformative segments in medical technology, driven by the rising adoption of 3D printing and digital fabrication across healthcare applications. Healthcare additive manufacturing—also known as 3D printing in healthcare—enables production of patient-specific implants, surgical guides, prosthetics, bioprinted tissues, and customized medical devices, offering unmatched precision, personalization, and cost-efficiency.

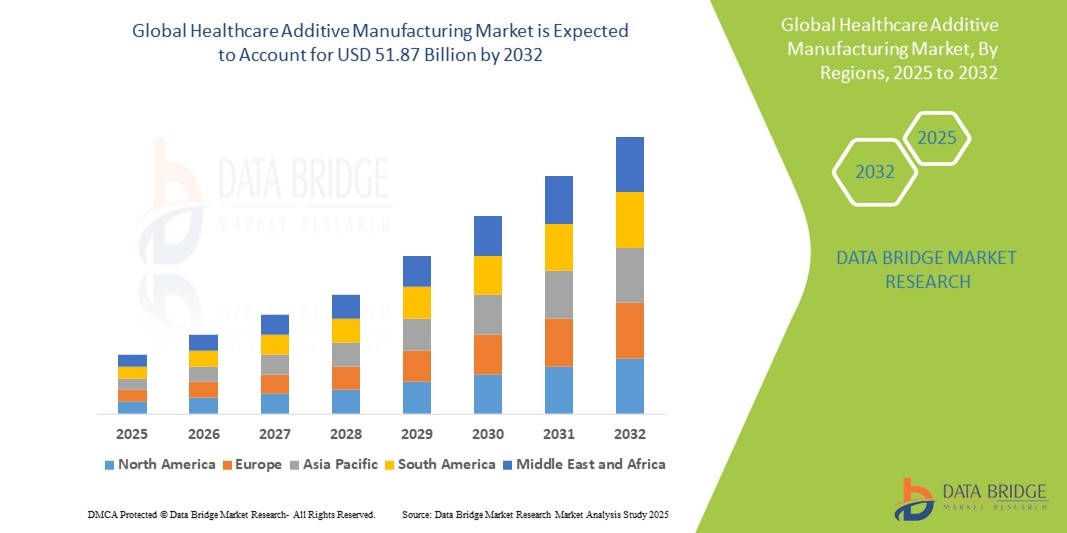

The healthcare additive manufacturing market size was valued at USD 10.92 billion in 2024 and is expected to reach USD 51.87 billion by 2032, at a CAGR of 21.50% during the forecast period. This rapid expansion reflects increasing clinical adoption, technological maturation, supportive regulatory frameworks, and growing healthcare investments in advanced manufacturing capabilities.

Get Expert Assistance for Detailed Industry and Market Questions @ https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-healthcare-additive-manufacturing-market

Key Market Trends

Surge in Personalized Medical Devices

Personalization is a leading catalyst for the healthcare additive manufacturing market. Patient-specific orthopedic implants, dental prosthetics, and craniomaxillofacial plates produced via 3D printing offer superior anatomical fit, reduced complications, and faster recovery times. Demand for customized solutions in orthopedics, dental restoration, and reconstructive surgery continues to grow, especially in aging populations and regions with rising disposable incomes.

Bioprinting and Tissue Engineering Advancements

A major trend reshaping the market is bioprinting, which uses additive manufacturing to layer living cells and biomaterials to form tissues and organ components. While full organ printing remains in developmental stages, bioprinted skin, cartilage, and bone tissues are increasingly used in research, drug testing, and regenerative medicine, expanding the application scope of healthcare additive manufacturing.

Integration with Digital Healthcare Ecosystems

Healthcare additive manufacturing is increasingly integrated with AI-enabled design, computer-aided engineering (CAE), and digital twin technologies. These systems optimize design workflows, simulate performance outcomes, and reduce trial-and-error in product development. Seamless integration with hospital information systems and imaging platforms enhances the ability to convert patient data (CT/MRI scans) into precise, ready-to-print digital models.

Regulatory and Quality Advancements

Regulatory frameworks for additive manufacturing in healthcare are maturing, with agencies providing clearer guidance on safety, validation, and quality control for 3D-printed medical products. Quality standards and material traceability protocols elevate clinician confidence and expand applications in surgical instruments, implants, and long-term medical devices.

Access a Free Sample Report Featuring Market Highlights and Trends @ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-healthcare-additive-manufacturing-market

Market Segmentation

The Healthcare Additive Manufacturing Market can be segmented by technology, material, component, application, end user, and region:

By Technology

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Fused Deposition Modeling (FDM)

Selective Laser Melting (SLM)

Electron Beam Melting (EBM)

Binder Jetting & Others

Stereolithography and Selective Laser Sintering dominate due to high precision, wide material compatibility, and extensive use in medical prototypes, implants, and models.

By Material

Polymers & Plastics (biocompatible polymers, resins)

Metals & Alloys (titanium, stainless steel, cobalt-chromium)

Ceramics & Composites

Bioinks & Biomaterials

Metals & biocompatible polymers are widely used in orthopedic implants, dental frameworks, and surgical instruments, while bioinks enable emerging tissue engineering applications.

By Component

Hardware (3D Printers & Scanners)

Software & Digital Solutions

Services (Consulting, Design & Prototyping)

Hardware accounts for the largest share, but software and services are growing rapidly with the adoption of digital design tools and outsourced manufacturing support.

By Application

Orthopedics & Prosthetics

Dental Solutions

Surgical Instruments & Guides

Bioprinting & Tissue Engineering

Pharmaceutical Manufacturing

Medical Education & Training Models

Orthopedics, dental solutions, and surgical guides currently lead market demand, while bioprinting and pharmaceutical applications represent high-growth future segments.

By End User

Hospitals & Clinics

Dental Clinics & Labs

Medical Device Manufacturers

Research Institutes & Biotech Firms

Contract Manufacturers

Demand from medical device manufacturers and hospitals is dominant, supported by rising adoption of point-of-care 3D printing units and outsourced additive services.

Regional Insights

North America

North America holds the largest share of the healthcare additive manufacturing market, supported by strong adoption of advanced technologies, extensive clinical applications, and well-established regulatory frameworks. The U.S. leads due to high healthcare spending, thriving med-tech innovation ecosystem, and early clinical adoption of 3D-printed implants and bioprinting research activities.

Europe

Europe represents a key market with robust demand in dental applications, orthopedics, and surgical instruments. Countries such as Germany, the UK, and France are investing in research and standardization initiatives, driving adoption across healthcare systems and manufacturing sectors.

Asia-Pacific

The Asia-Pacific region is projected to register the fastest growth through 2032. Expansion is driven by rising healthcare infrastructure investments, increasing public and private funding for additive manufacturing initiatives, growing medical device industries, and expanding university-industry partnerships. China, Japan, India, and South Korea are central to regional market momentum.

Latin America & Middle East & Africa

These regions are emerging markets with increasing adoption of healthcare additive manufacturing in dental labs, prototyping services, and academic research. Growth is supported by improvements in healthcare infrastructure and growing partnerships with global technology providers.

Emerging Opportunities

Point-of-Care Additive Manufacturing

Deploying additive manufacturing units directly within hospitals and surgical centers enables rapid production of patient-specific implants, prosthetics, and surgical models, reducing lead times and enhancing personalized care.

Pharmaceutical Additive Manufacturing

Additive manufacturing in drug development and delivery holds potential to manufacture complex dosage forms, controlled-release structures, and personalized medications, creating a new frontier in precision pharmacotherapy.

Regenerative Medicine & Organ Printing

While still in early stages, bioprinting of tissues and organ components offers transformative opportunities in regenerative medicine. Commercialization of bioprinted tissues for grafting and drug testing is expected to grow, with long-term potential for full organ fabrication.

Subscription & Managed Service Models

Healthcare providers and manufacturers are moving toward subscription-based software platforms and managed 3D printing services, lowering entry barriers for smaller clinics and labs while generating recurring revenues for technology vendors.

Access the Full Market Report with Detailed Forecast and Insights @ https://www.databridgemarketresearch.com/checkout/buy/global-healthcare-additive-manufacturing-market/compare-licence

Competitive Landscape

The Healthcare Additive Manufacturing Market is moderately competitive and rapidly evolving, featuring major med-tech innovators, 3D printing specialists, software developers, bioprinting startups, and contract service providers. Competitive strategies include:

Technology Innovation: Advancing printer performance, material compatibility, and digital design capabilities.

Strategic Partnerships: Collaborating with hospitals, dental labs, research institutes, and OEMs to co-develop solutions.

Service Expansion: Offering design consultation, prototyping services, training, and managed additive manufacturing support.

Regional Expansion: Establishing localized service hubs and training facilities to support global demand.

Market leadership is increasingly shaped by integration of digital workflows, regulatory compliance support, and end-to-end service portfolios that accelerate adoption across healthcare segments.

Frequently Asked Questions (FAQ)

Q1: What is healthcare additive manufacturing?

A1: It refers to using 3D printing technologies in healthcare to produce customized medical devices, surgical instruments, prosthetics, implants, bioprinted tissues, and training models with high precision and personalization.

Q2: What is driving the growth of the healthcare additive manufacturing market?

A2: Key drivers include demand for personalized implants, technological advancements, regulatory clarity, integration with digital design tools, and rising investments in hospital-based 3D printing solutions.

Q3: Which applications dominate this market?

A3: Orthopedics, dental solutions, and surgical instruments are dominant, while bioprinting and pharmaceutical manufacturing are high-growth future segments.

Q4: Which region is expected to grow fastest?

A4: The Asia-Pacific region is projected to grow fastest due to expanding healthcare infrastructure, rising R&D investments, and increasing adoption of additive technologies.

Q5: What are key emerging opportunities?

A5: Opportunities include point-of-care additive manufacturing, pharmaceutical 3D printing, regenerative medicine, and subscription service models.

Q6: How is 3D printing reshaping healthcare?

A6: It enables customization of patient-specific medical solutions, rapid prototyping for surgical planning, cost-efficient device production, and potential for tissue engineering and regenerative therapies.

For more reports

Packaged Coconut Water Market

Household Cleaning Tools and Supplies Market

Construction and Demolition Waste Market

About Us:

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact:

Data Bridge Market Research Private Ltd.

3665 Kingsway — Suite 300

Vancouver BC V5R 5W2

Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)

Email: Sales@databridgemarketresearch.com

Website: https://www.databridgemarketresearch.com/